Forged Steel Fittings

Inventory

First Distributors can often provide the items listed below for a same-day delivery. Large quantites, custom sizes, and special alloys (Alloy 20, Monel, Hastelloy, Inconel, Titanium, etc) may be subject to a longer lead time for delivery.

Standard Sizes Available “On the Shelf”:

| NPS Diameter Range | |||

|---|---|---|---|

| Material | Construction | Min | Max |

| Carbon Steel | Seamless | 1/8” | 24” |

| Welded | 1/2” | 48” | |

| Stainless Steel | Seamless | 1/4” | 24” |

| Welded | 1/4” | 36” | |

| Special Alloy | Seamless | 1/2” | 8” |

| Welded | 6” | 12” | |

MaterialS We Offer

Carbon & Stainless

- Standard Carbon Steel Fittings (A105): ASTM A105 is an ASTM specification dealing with forged carbon steel piping components

- Stainless Steel Fittings (A182): This specification covers forged or rolled alloy and stainless steel (304, 304L, 316L) forged fittings. This spec also covers other alloys including chrome (i.e. A182 F11)

Special Alloy

- Alloy 20

- Duplex 2205

- Super Duplex 2507

- Hastelloy C276

- Incoloy 800

- Incoloy 825

- Monel 400

- Inconel 625

Pressure Classes Available

Pressure - Temperature Service Ratings for Carbon Steel Forged Steel Socket Welding and Threaded Fittings

| Service | Nominal Pressure Rating | ||

|---|---|---|---|

| Temperature (°F) | 2000 LB. | 3000 LB. | 6000 LB. |

| 100° | 2000 | 3000 | 6000 |

| 150° | 1970 | 2950 | 5915 |

| 200° | 1940 | 2915 | 5830 |

| 250° | 1915 | 2875 | 5750 |

| 300° | 1895 | 2845 | 5690 |

| 350° | 1875 | 2810 | 5625 |

| 400° | 1850 | 2775 | 5550 |

| 450° | 1810 | 2715 | 5430 |

| 500° | 1735 | 2605 | 5210 |

| 550° | 1640 | 2460 | 4925 |

| 600° | 1540 | 2310 | 4620 |

| 650° | 1430 | 2150 | 4300 |

| 700° | 1305 | 1960 | 3920 |

| 750° | 1180 | 1775 | 3550 |

| 800° | 1015 | 1525 | 3050 |

| 850° | 830* | 1250* | 2500* |

| 875° | 725* | 1090* | 2180* |

| 900° | 615* | 925* | 1855** |

| 925° | 520* | 785* | 1570** |

| 950° | 425** | 640** | 1295** |

| 975° | 330* | 500** | 1000** |

| 1000° | 235** | 350** | 715** |

A Guide to FORGED STEEL FITTING SHAPES/TYPES

Forged steel fittings are manufactured in a number of shapes:

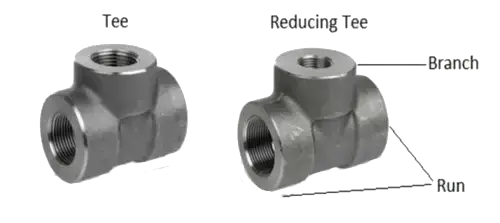

Tees

Tees are used to combine or divide process flow, and Reducing Tees additionally allow for pipe size change. The run outlets of the tee are the two in-line outlets, and the branch is the third outlet. The branch outlet is the reducing outlet in a reducing tee.

Elbows

A pipe elbow is a fitting installed between two lengths of pipe or tube allowing a change of direction, usually in the 90° or 45° direction. Similar to a reducing tee, reducing elbows also exist to simultaneously change flow direction and reduce flow diameter. Street Elbows have one female end to accept pipe and another male end thread that is the same size as the pipe and can avoid the use of a pipe nipple during installation.

Couplings

Couplings are used to connect two lengths of pipe, and Half-coupling is screwed onto the pipe, while the other end is made to be tightly inserted, or welded, onto the other end to pipe or vessel.

Couplings are used to connect two lengths of pipe, and Half-coupling is screwed onto the pipe, while the other end is made to be tightly inserted, or welded, onto the other end to pipe or vessel.

Unions

Unions are similar to a coupling but allow a convenient disconnection and connection; it has 3 parts: a nut, a female end, and a male end. They allows two lengths of pipe to be assembled and detached without causing any deformation to the pipes.

Bushings

Reducing inserts and Bushings allow for a change in pipe size. Pictured here is the hex head bushing, which is most commonly used.

Caps

Caps are used to terminate the flow, inserting over the end of the pipe

Plug

Similar to a cap, plugs are inserted into the end of the pipe, and they come with different head types, including: hex, square, and round.

Plug

Crosses are a 4 way fitting, with 1 inlet and 3 outlets or vice versa. These are sometimes referred to as 4-way tees.

End Connection

Forged Steel fittings are available in threaded and socket weld end connections.

The dimensions for Socket Weld fitting conform to ASME B16.11 and threaded fittings conform to ASME (American Society of Mechanical Engineers) B1.20.1.

Commonly Found Manufacturers

| Approved Branch Fittings Manufacturers | Country |

|---|---|

| Bonney Forge | Canada/Italy |

| Capitol Camco | USA |

| Phoenix Forge | USA |

| IMF | USA |