Ball Valves

Inventory

First Distributors offers a wide range of carbon steel, stainless steel, and even exotic alloy ball valves..

| Size Range: | 1/4" - 36" Diameter |

| Body: | 2PC, 3PC, 1PC |

| Floating: | Ball is floating and will drift with the flow of media |

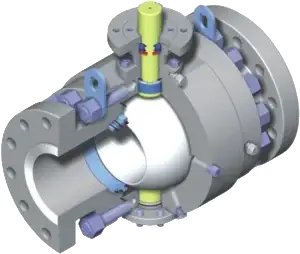

| Trunnion: | Mechanical anchoring of the ball at the top and bottom at the valve, for use in higher pressure situations |

| Types: | Quarter Turn: (Ball, Butterfly, Plug), Gate, Globe, Check, and Relief Valves |

| End Connection: | Flanged (RF, FF, and RTJ), Threaded, Socketweld, Buttweld |

| Materials: | Alloy 20, Aluminum Bronze, Bronze, Carbon Steel (WCB, A105), Cast Iron, Ductile Iron, F5, F9, F11, F22, F91, Hastelloy C, Monel/Inconel, LF2, LCB, LCC, Stainless Steel (316, 304, 304H, 347), WC6, WC9, C5, C12, C12A, FORGED BRASS (B283, C37700) |

| Pressure Class: | (FLANGED) 150# 300# 600# 900# 1500# 2500#...(THREADED, SOCKET WELD) 800# 1000@ 1500# 2000# 2500# 3000# 6000#... |

| Ball & Stem: | Carbon Steel, Carbon Steel and Electroless Nickel Plating, Stainless Steel, Monel, etc |

| Soft Goods (Seats, Seals and Stem Seal): | Teflon, Reinforced Teflon, Graphite Filled, Peek, Metal, etc |

| End Connections: | Threaded, Socket weld, Flanged (RF FF RTJ), Butt-weld |

| Port: | Full or reduced: Full has oversized ball same size as pipeline, reduced is smaller than the pipeline |

| Actuation: | Most valves can have an actuator installed to make opening and closing easier. |

| Special Trims: | 316 Stainless, Alloy 20, Aluminum Bronze, Bronze, Monel, NACE, and Full Stellite |

| Brands: |

Materials Available

Most ball valves are going to be cast steel or forged steel. The main difference with forged steel is that they are going to be for high-pressure applications. In addition to the materials below, many other grades of stainless and exotic alloys are also available

Actuation Available

Manual operators, such as gears, are relatively inexpensive and require little peripheral planning beyond the installation and orientation of operators in the process line. Gears are simple machines that utilize a series of mechanical parts to increase efficiency – the mechanical advantage that the user gains.

Torque is a function of force and distance – the required force (rim pull) required to open or close the valve can be decreased by increasing the length of the lever or diameter of the handwheel mounted on the valve. The industry defines specifications for the highest values personnel should exert on levers or handwheels to operate a valve. Current API specifications limit pull to 360 Newtons (80 pounds-force). The maximum lever length or handwheel diameter also is limited by industry specifications.

- Lever Handle – usually ¼” turn, as it states you operate the ball with a lever by hand. The lever will turn the ball in either a floating or trunnion ball valve, letting the opening allow media to flow through or be stopped.

- Handwheel - the hand wheel operates the ball by physical force and turns the ball open or closed.

- Gear Operator – uses gears to reduce the amount of force required to open and close the ball on the valve.

- Actuator – Takes the physical component of operating the valve out of the equations and will operate the valve automatically, usually by switches (Hydraulic, Electrometer, and Pneumatic)

A Guide To Body Configurations (style Of Ball Valves)

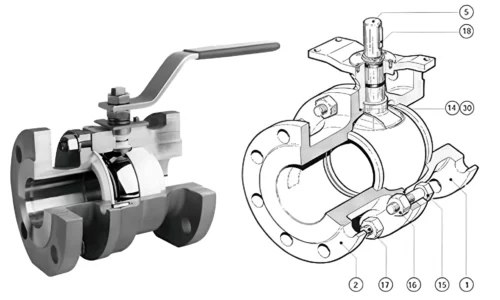

You can get ball valves generally in five different styles: single body, two-piece body, three-piece body, top entry and welded. The most common are single, double and three piece. The differences are the configuration related to the bore of the ball mechanism itself, but functionality remains the same. Ball valves are also broken down into two main types (Trunnion and Floating), which we will go into further details below.

Trunnion Ball Valves

Floating Ball Valves

End Connections Overview:

- Threaded – A very common end connection, this will normally come in female national pipe thread (FNPT). The valve will be screwed or threaded on to the pipeline.

- Socket weld – the end connection is counter bored and the pipe will be inserted and butted up to the inner lip of the end connection then fillet welded around.

- ThreadX SocketWeld – Since ball valves are bi-directional you can have thread x socket weld, but do not need to specify which end is which.

- Flanged – Will have flanges installed on the valves to be installed directly into the pipeline.

FULL PORT VS. REDUCED PORT

- Threaded – A very common end connection, this will normally come in female national pipe thread (FNPT). The valve will be screwed or threaded on to the pipeline.

- Socket weld – the end connection is counter bored and the pipe will be inserted and butted up to the inner lip of the end connection then fillet welded around.

- ThreadX SocketWeld – Since ball valves are bi-directional you can have thread x socket weld, but do not need to specify which end is which.

- Flanged – Will have flanges installed on the valves to be installed directly into the pipeline.