Pipe Nipples & Swages

Inventory

First Distributors can often provide the items listed below for a same-day delivery. Large quantities, custom sizes, and special alloys (Alloy 20, Monel, Hastelloy, Inconel, Titanium, etc) may be subject to a longer lead time for delivery.

| Size Range: | 1/8" - 6" Diameter |

| End Connections: | Threaded, Plain, Beveled |

| Schedules: | 40 (STD), 80 (XH), SCH160, XXH |

| Carbon Steel: | A106, A53, A350, A234 (swages only) |

| Stainless Steel: | 304, 316, 321, 347 |

| Exotic Alloys: | Alloy 20, C276, Duplex 2205, Duplex 2507, Monel, Inconel, Incoloy 800, Incoloy 825 |

Overview & Application

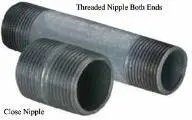

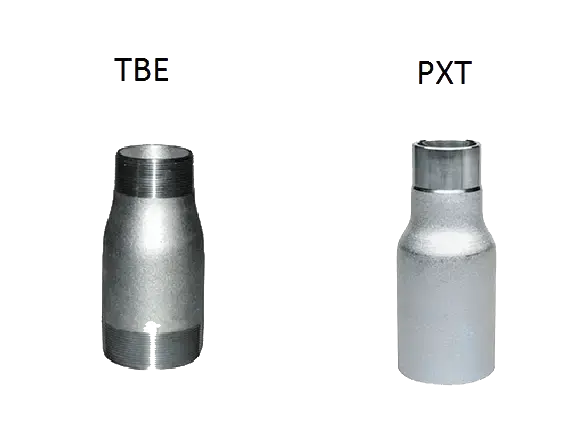

A nipple is a fitting, consisting of a short piece of pipe, usually provided with a male pipe thread at each end, for connecting two other fittings or pipeline components. Nipples are commonly used as adapters from one connection type to another. Similar to a nipple in many ways, a swage is a reducing nipple, used to connect two different sized fittings.

Concentric

Eccentric

A Guide to Dimensions, Material, and Construction

For swages, like reducing nipples, they come in two types: concentric and eccentric. These are shown below. Also, rather than being manufactured to pipe material specifications, carbon steel swages come in A234, and they are always seamless in construction. Lastly, please note that since each end of a swage is of a different size, the wall thickness (schedule) of each side can also be different.

Length

End Connections

Common end connections for pipe nipples are plain both ends (PBE), threaded both ends (TBE), beveled ends (BBE), threaded one end (TOE), beveled one end (BOE), plain one end (POE) or a combination thereof, depending on the ends of the piping system into which the nipple will be fitted.

When listing the end connections of a swage, unlike a pipe nipple, the order matters. The end connection of the larger OD is listed first, and the smaller OD second. There are several end connections/combinations available for swages: threaded both ends (TBE), threaded by plain (TXP), plain by threaded (PXT), plain both ends (PBE), beveled by threaded (BXT) or other combinations of plain, threaded, and beveled. The end connections of the swage depends on the end connections of the piping system into which the swage will be fitted.

Note: Industry language sometimes includes specifications such as "PSE x TLE", which simply means plain short end by threaded long end; the "S" stands for short and the "L" stands for long.