Buttweld fittings

Inventory

First Distributors can often provide the items listed below for a same-day or next-day delivery. Large quantites, custom sizes, and special alloys (Alloy 20, Monel, Hastelloy, Inconel, Titanium, etc) may be subject to a longer lead time for delivery.

| Size Range: | 1/4" to 48" Diameter |

| Types: | 90, 45, 180, Tee, Cross, Ecc Reducer, Conc Reducer, Cap |

| Schedules: | 5, 10, 40 (STD), TRUE 40, 80 (XH), TRUE 80, 100, 120, 160, XXH |

| Carbon Steel: | A234 WPB, Y52, Y60, Y65, Y70 |

| Stainless Steel: | 304, 316 |

| Exotic Alloys: | A20, C276, Duplex 2205, Duplex 2507, Monel, Inconel 600, Inconel 625, Incoloy 800, Incoloy 825 |

A Guide to the Materials Available

The following offers an in-depth view of the material grades sold by First Distributors. Each link below will provide the chemical composition, manufacturing specifications, yield and tensile strength, as well as other specific product and grade information.

1. Carbon Steel Butt Weld Fittings

2. Stainless Steel Pipe

3. Special Alloy Steel Pipe

- Alloy 20

- Duplex 2205

- Super Duplex 2507

- Hastelloy C276

- Incoloy 800

- Incoloy 825

- Monel 400

- Inconel 600

- Inconel 625

A Guide to Shapes and Types of Butt Weld Fittings

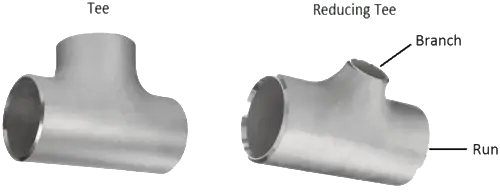

Tees

Nipples can come to any specified length, but most commonly range between close to 12”. A close nipple is the shortest piece of pipe necessary to allow for fully threaded end connections, where there is no smooth surface between threads.

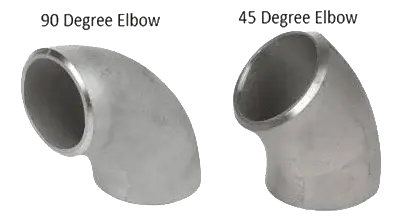

Elbows

A pipe elbow is a fitting is used to change the direction of flow in a piping system, usually at the 90° or 45° angle. Like a reducing tee, reducing elbows also exist to simultaneously change flow direction and reduce flow diameter. 90 degree elbows are also available in both short radius and long radius patterns , whereas 45 degree elbows are only available as long radius.

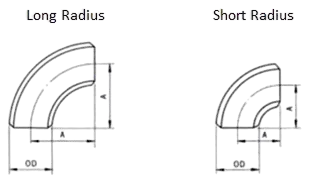

Long Radius (LR) vs Short Radius (SR)

A long radius elbow has a radius of curvature (Identified as “A” in the above drawing) is 1.5 times the nominal diameter, and a short radius elbow has a curvature that is 1.0 times the nominal diameter of the pipe. Long radius elbows give less frictional resistance to the fluid than the short radius elbows. Short radius are generally cheaper and can be used where space is a concern, but they also create a greater pressure drop than long radius.

Bend vs Elbow

There is often confusion around bends and elbows. Bends are generally made or fabricated as per the need of the piping design, whereas elbows are manufactured in mass quantities, conform to industry standard size specifications, and available off the shelf. Pipe bending techniques also face constraints regarding material thinning, and if not done properly, there can be concerns regarding the pressure integrity of the line being maintained. Elbows are most commonly used for SR and LR bends, but when the curvature exceeds 3R, bends are most commonly utilized.

Reducers

Reducers are used to facilitate a reduce the flow diameter in a piping system. Concentric reducers are most commonly used, as they create less friction for the fluid flow, however, eccentric reducers are utilized when space or alignment is a concern.

Cross

Crosses are a 4 way fitting, with 1 inlet and 3 outlets or vice versa. These are sometimes referred to as 4-way tees.

Caps

Caps are used to terminate the flow, welding to the end of the pipe.

Commonly Found Manufacturers

| Approved Carbon Steel Butt Weld Fittings Manufacturers | Country |

|---|---|

| Awaji Sangyo K.K. | Japan |

| Benkan | Japan |

| Canadoil Forge LTD | Canada |

| Erne Fittings | Austria |

| Flo-Bend Inc | USA |

| Hackney Ladish Inc | USA |

| Mills Iron Works | USA |

| Piana S.p.A. | Italy |

| Proclad International Forging Ltd | UK |

| Promat BD Ltd | UK |

| PSL Limited | India |

| RMA Machinen und Armaturenbau | Germany |

| Shaw Alloy piping products (APP) | USA |

| Steel Forgings, Inc | USA |

| Tae Kwang Bend | KOREA |

| Tecnoforge S.p.A. | Italy |

| Tectubi | Italy |

| Tenaris Riga | Mexico |

| Thai Benkan Co Ltd | Thailand |

| Tube Forgings of America Inc. | USA |

| Tube Line | India |

| Uhlig | German |

| Viar Meccanica Srl | Italy |

| Weldbend Corporation | USA |

| Westbrook | USA |

| WFI | USA |

| Wilhelm Geldbach Industries | Germany |

| Approved Stainless Steel Butt Weld Fittings Manufacturers | Country |

|---|---|

| Canadoil Forge LTD | Canada |

| Erne Fittings | Austria |

| Erne Fittings | Austria |

| Jiangsu Huayang | China |

| Proclad International Forging Ltd | UK |

| Promat BD Ltd | UK |

| RMA Machinen und Armaturenbau | Germany |

| Shaw Alloy piping products (APP) | UK |

| Tae Kwang Bend | KOREA |

| Taylor Forge of Canada | Domestic |

| Tecnoforge S.p.A. | Italy |

| Tectubi | Italy |

| Thai Benkan Co Ltd | Thailand |

| Tube Line | India |

| Uhlig | German |

| Viar Meccanica Srl | Italy |

| Westbrook | USA |

| WFI | USA |

| Wilhelm Geldbach Industries | Germany |

| Wilhelm Schulz | Germany |